Well my run of luck continued today with Jeremy's Les Paul build. Maybe rather then luck it's care and attention to detail? Hmm, doesn't sound like me. Whatever it is, Jeremy's axe is shaping up to be one of the nicest builds I've ever done

touch wood. When all this is over I may have to go back and make myself one!

With the flame maple cap dyed a couple of days ago, it was time to get on and colour the rest of the guitar. Before I could dye the neck, however, I had to spray the headstock black. The reason I wanted to do this before dying the rest of the neck was so that I could use sand paper to clean up the side of the headstock where the paint meets the wood. If the dye was already on there, then sanding the edge clean would have easily ruined the dye job.

Anyway, I filled the pores of the headstock face with a Timbermate slurry and sanded it off flat with 400 grit. Straight on to this went 4 coats of black auto paint. I forwent the obligatory primer coats because I didn't want a white line around the edge where the paint meets the wood. It really wasn't necessary. After 2 coats I cleaned up the sides and then wet sanded with 600 grit. After the 4th coat I did the same this time wet sanding with 1500. What I ended up with was a nice flat paint job ready for clear coats.

|

| Ready for clear after 4 coats of paint and two rounds of wet sanding |

With the sides nice and tidy, the painters tape went back on and I laid down 4 coats of acrylic clear. The main purpose for doing this now (I reasoned) was to get a protective coat on there so that I could manhandle the neck during subsequent finishing without taking colour off.

|

| Four coats of acrylic clear. Now I can get back to the dye. |

The acrylic went on very easily, and after 4 coats I was satisfied that the face was adequately protected. I left it to cure overnight and then cleaned up the side of the headstock with 600 grit. At last I was ready to get the dye out again!

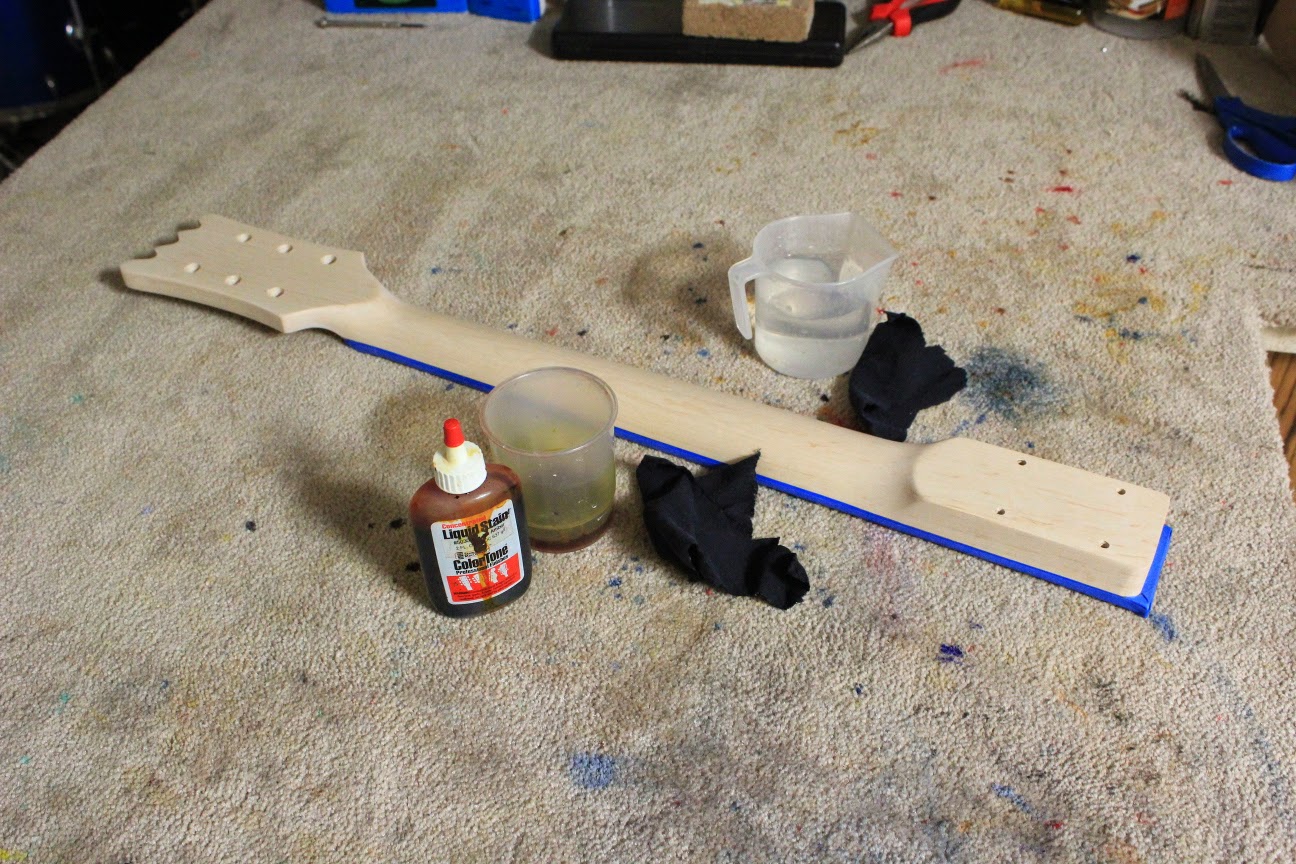

To colour the neck and body I used a 4:1 ratio of Colortone Vintage Amber and Red Mahogany. In the last stages of the burst I actually used a 1:1 mix of same, but with the mahogany neck and body being a naturally darker wood than the maple cap, considerably less red was needed to match the colour. I actually had to guess at this ratio, but managed to fluke a good match between burst and body on the first try.

The dye itself went on smoothly (preparation pays off kids!), although I do wish I had protected the dyed veneer before starting - juggling the body with a mind to not damaging the burst wasn't much fun. I made about 4 passes of dye on both pieces and hung them up to dry. The grain in both the body and the neck is pretty damn nice on this kit I must say!

|

| Some amazing grain in this body. Tru-Oil will get it to pop. |

|

| The colour match between the body and burst is great. |

|

|

|

|

Once the body was completed I went on to do the neck. Getting the stain on to the sides of the headstock without damaging (or even disturbing) the black was a little stressful, but I got there in the end. I'm really happy with the results and, as with the body, the grain on the mahogany neck has become a thing of beauty!

|

| Neck is now all dyed. More amazing figure. |

I hung the body and neck to dry a few hours in the patented Turner drying room (our shower recess ;) to make sure the wood was completely dry. I then applied my first coat of Tru-Oil to both the neck and body. The neck is going to be finished in Tru-Oil so this is the first coat of many for it. The body on the other hand will be clear coated with acrylic. The Tru-Oil on the body is only there to help pop the grain which it does sooo well. Lacquer on its own just can't hope to emulate what the oil does in the figure. When mixing TruOil and lacquer, you just have to make sure that you don't make the surface shiny at all. For this body there will be only a few coats, and I definitely won't be sanding between coats.

|

| First coat of Tru-Oil on the body has really popped the grain. |

As the Tru-Oil went on, the grain really started to leap out from these pieces, and I'm really pleased with how the body is looking. I'd like to do the same (Tru-Oil) for the front face of the guitar as well, but I'm worried that the oil will drag some of the colour out from the glue spots I fixed earlier in the week. It definitely isn't worth the risk IMO. A couple more coats of Tru-Oil on the body, and a week or two for the smell to go completely, and the body will be ready for final clear coats. In the meantime I'll get start on the Tru-Oil coats for the neck!